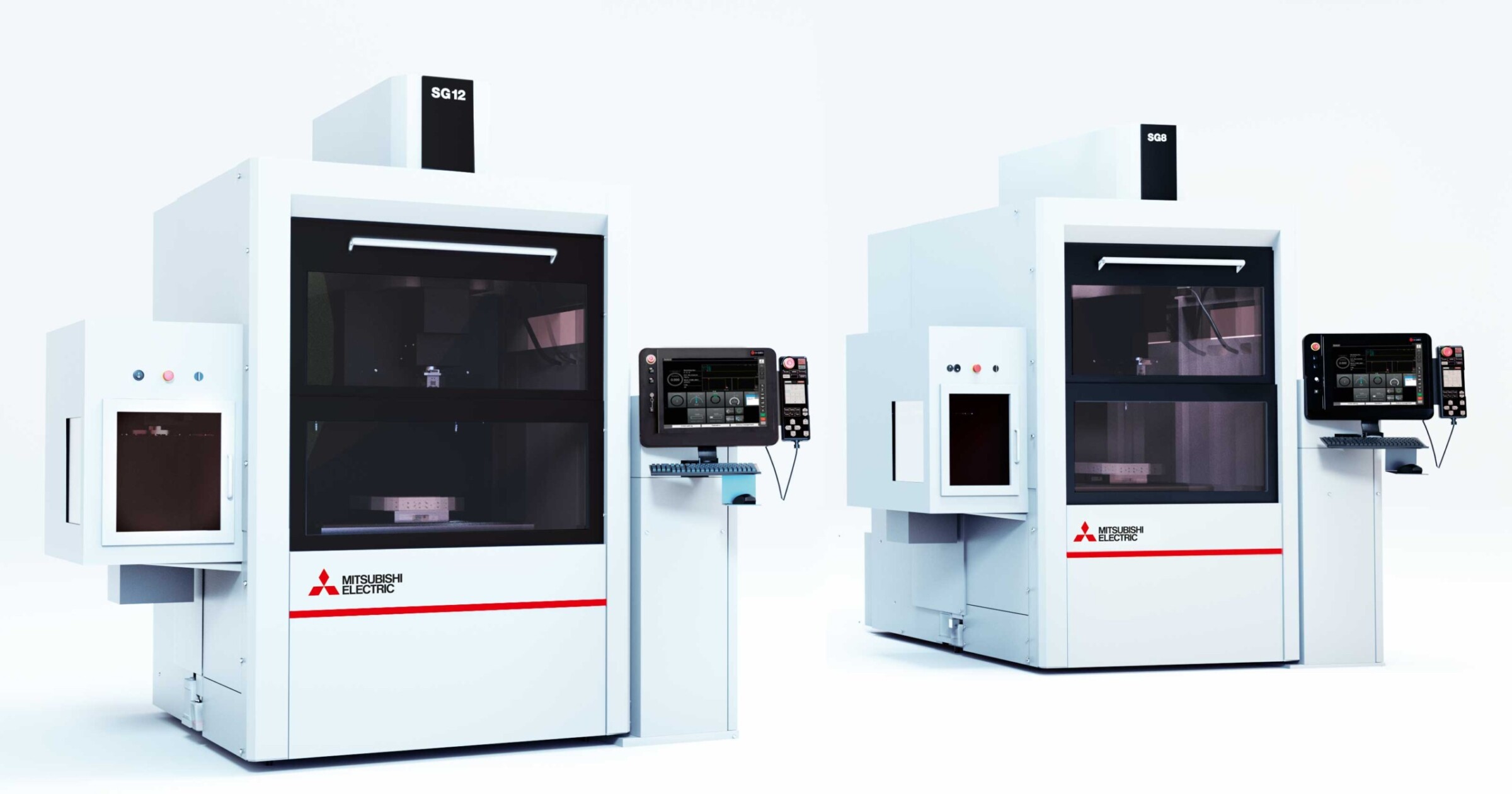

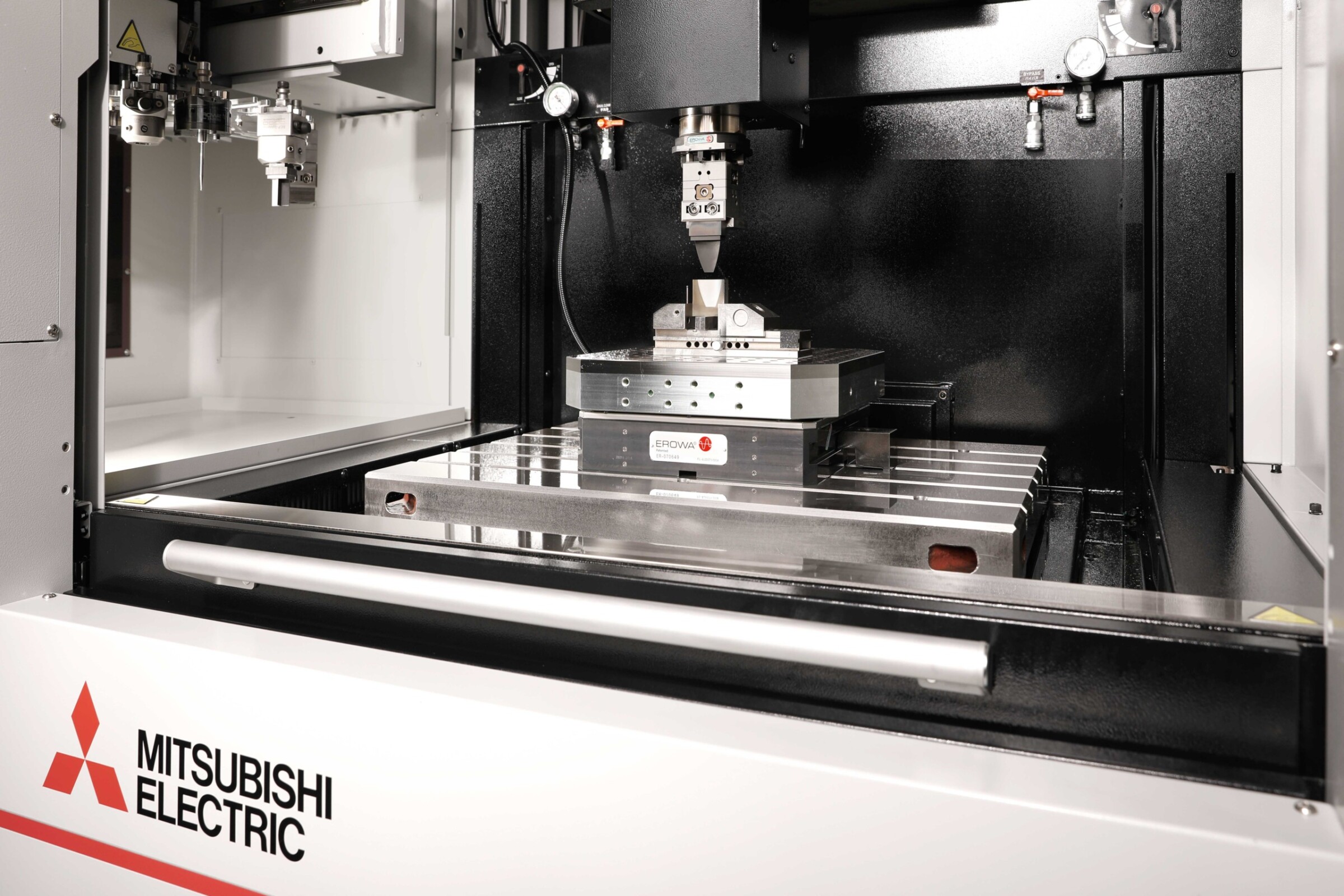

Behind every dependable, precision EDM machine is sound engineering. In addition, the technological nerve centre of every EDM is its electronics. Whether CNC control, axis drives or erosion generator – here everything comes from a single source: Mitsubishi Electric.

Precision sinking with artificial thinking. But that’s not the only thing that’s new …

The SG series banks on steel – a great deal of steel – as an assurance of precision and longevity. The use of the best components, such as glass scales from Mitutoyo, also guarantees the reliability of the machine system over a long machine life. Its straightforward operation and programming – a hallmark of Mitsubishi Electric’s die-sinking EDM systems – leaves the operator time for the essential, i.e. the proper planning of the various EDM tasks. And here, too, this is aided by the intelligent control strategy with integrated job planning. This way the user benefits from the evaluation of a wide range of operating data, including actual job costing.

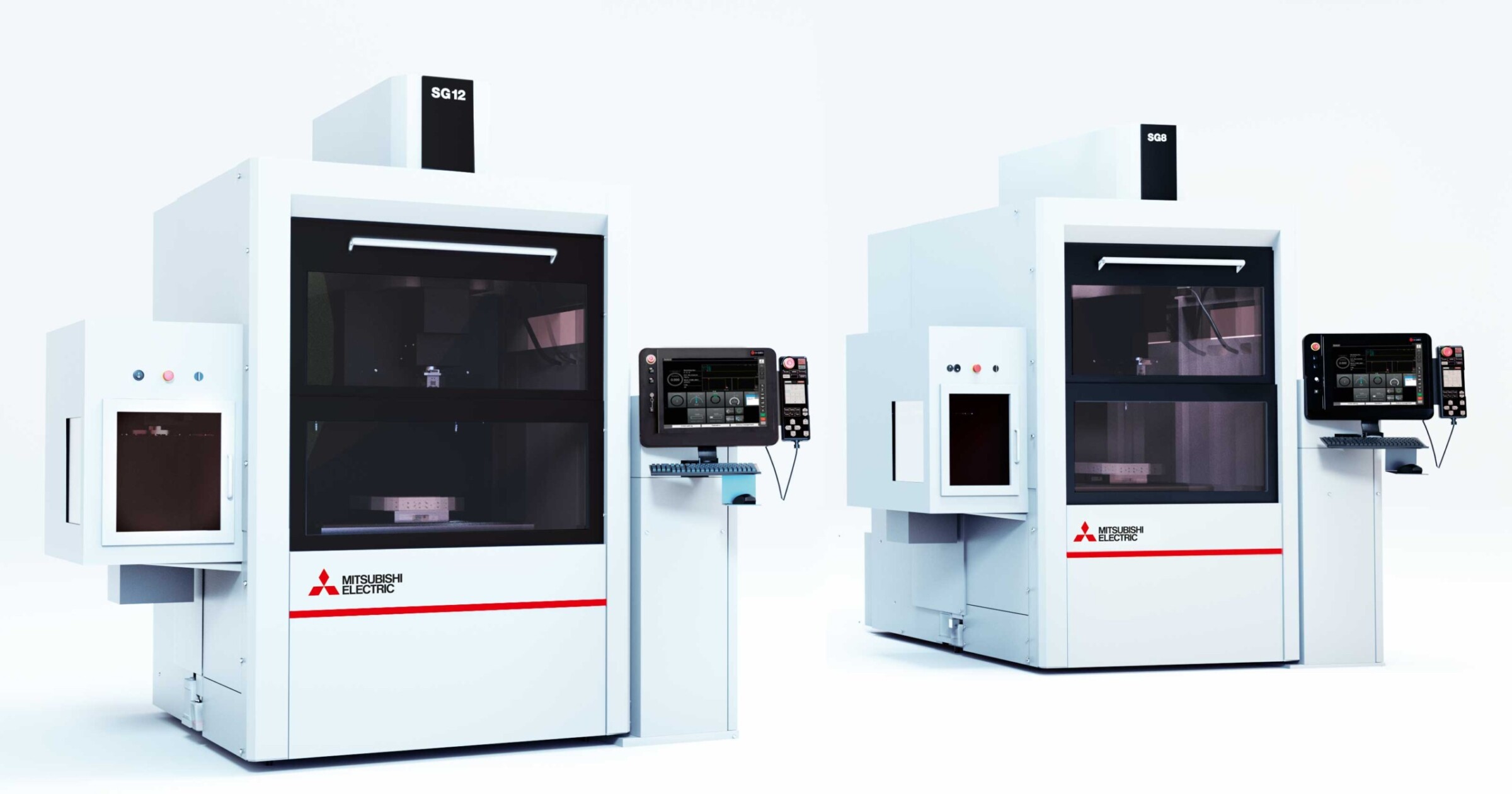

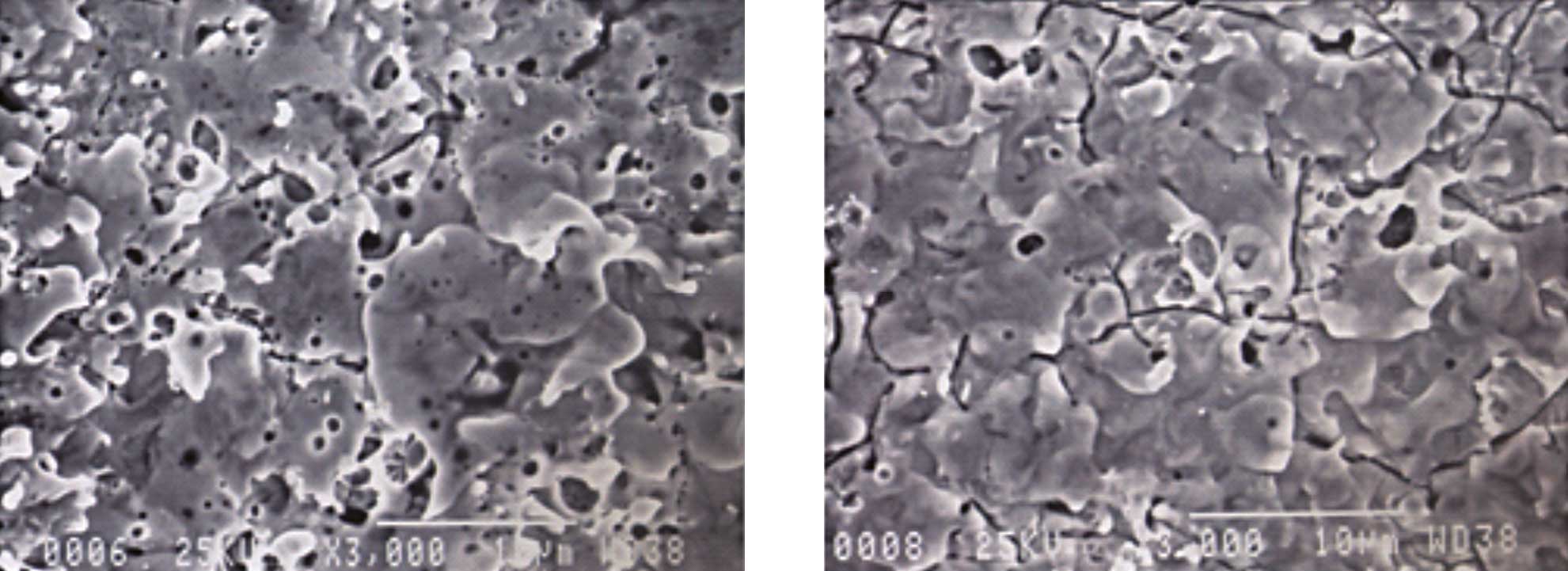

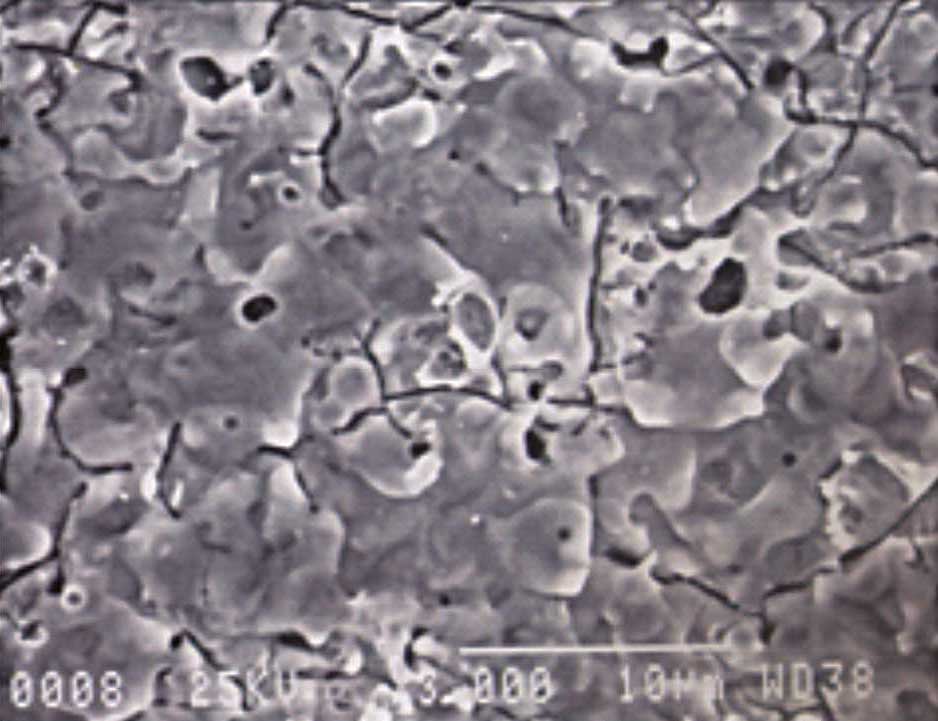

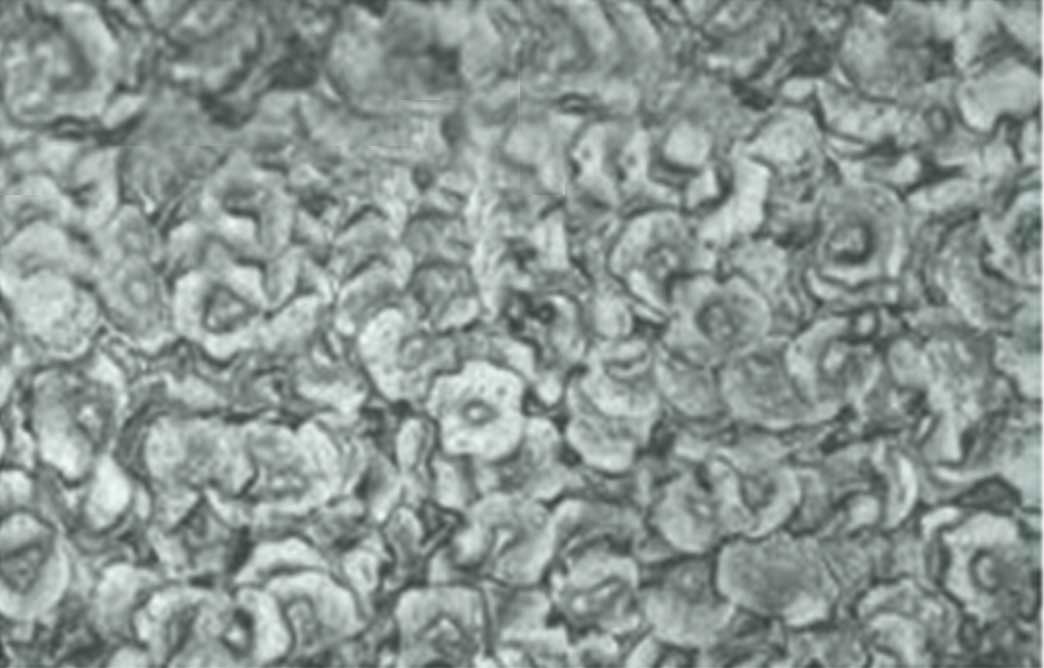

Micro-cracking in carbide? No thanks!

Too aggressively eroded: identifiable microcracks

Eroded with the SG-R: full material removal with minimal microcracking

The D-CUBES control generation excels with the Artificial Intelligence developed by Mitsubishi Electric. Forward-looking machining strategies are applied in a self-learning process. The automatic adaptation of the lift-off paths and immersion strategy ensures a continuously optimised erosion process – resulting in a real leap forward in productivity. To suit the actual conditions in the process, the generator parameters are also continuously adapted – for an optimum, low-wear erosion process. At the same time, there is plenty of performance in reserve thanks to the 80 A or optionally 120 A generator. The GV Generator is designed for a wide range of applications and is supported by the digital Power Master IDPM. The outcome is superlative performance with extremely low electrode wear by using graphite electrodes as well as the creation of intricate details and high surface qualities with copper electrodes. Special adaptations for carbide, titanium and PCD are available for a wide range of applications, so that the user is optimally equipped for virtually all challenges.

Willi Reichert, Managing Director Willi Reichert GmbH

I’m very satisfied with the Mitsubishi SG12S. I was able to erode several top-quality workpieces within a week. The decision to buy it was absolutely right. Even the modern touch screen control is no problem for me as a 67-year-old user and greatly simplifies my work.

The newly developed drive unit of the Z axis operates soundly and precisely with an acceleration of up to 1.6 G and travel speeds of up to 20 m/min. By using the in-house AI technology, these lift-off movements are neatly controlled – for an efficient and stable erosion process in every situation.

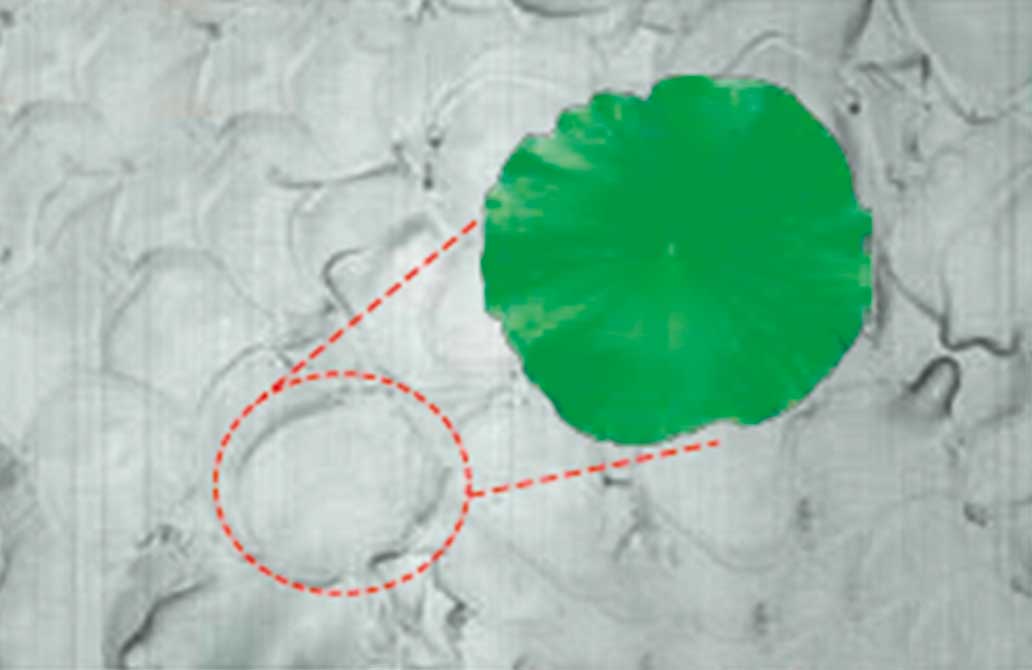

Conventionally machined surface

LLTX lotus effect

LLTX lotus effect technology

Sometimes programming at the machine itself is the fastest and most efficient way to achieve your goal. More often, however, external programming at the PC is the more convenient and effective choice. Ergonomically optimised, without distraction and with all the convenience of programming while the machines do their job. The external programming software is included in the SG-R’s standard package.

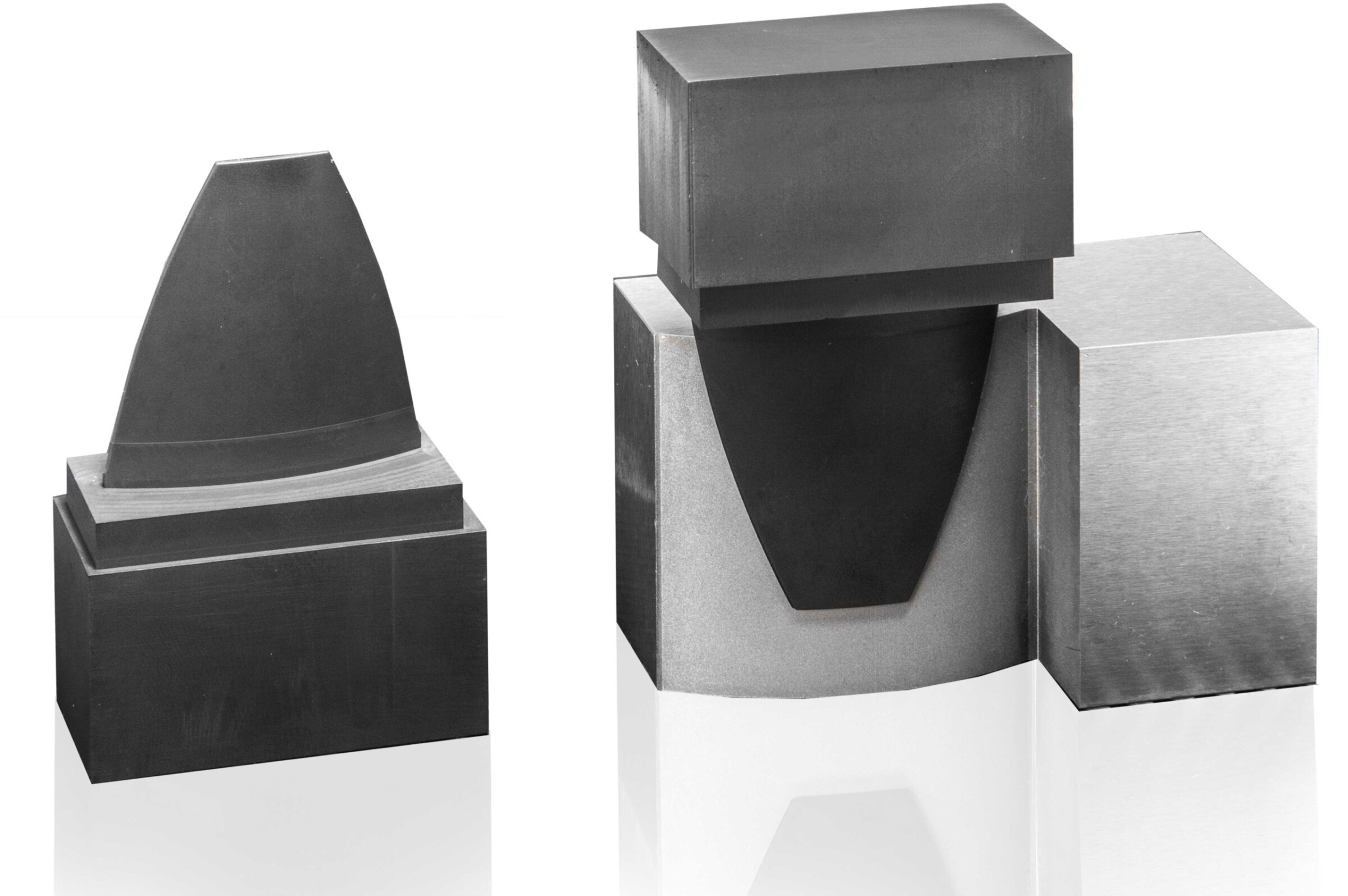

The formation of deep ribs with a uniform surface structure is a feature of the IDPM Power Master.

The standard full range of equipment on the SG-R completes the package. A fire extinguishing system, C axis with a zero point clamping system, external programming software, integrated job planning and operating data output with many status details (also via MTConnect) – all this is included in the machine’s standard equipment. The overall scope of delivery can be customised with a few, useful extra features – tailored to the respective requirements.

Ideally equipped for all tasks.

The extensive equipment, pioneering technology and familiar sound engineering come at a price that makes buyers‘ hearts beat faster. The SG-R series will find many discerning followers.

The advanced D-CUBES M800 control supports the operator in every situation. It handles routine tasks and takes the effort out of programming.

Very best value for money.

Cost-effective machining due to low electrode wear

The newly developed drive unit of the Z axis

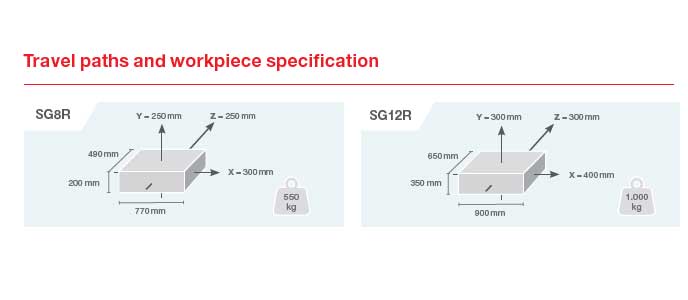

Travel paths and workpiece specification

Name of company:

Mitsubishi Electric

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com