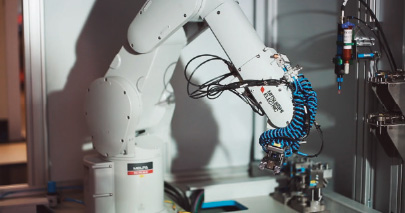

The handling systems and robots from different manufacturers can often be seamlessly integrated. Renowned for their dependability and productivity, the EDMs of the MV-R series from Mitsubishi Electric are automation-ready. We’d be happy to show you examples that have proven effective in practice and help you to cut costs and boost your productive capacity.

Welcome to our quick navigation. Here you can directly select a topic that you are particularly interested in. You will then be directed to this topic.

At Mitsubishi Electric, it is not only our staff members that work hand in hand with one another. The robots do as well. Produce 24 hours a day, 7 days a week.

Up to 8 further extra axes can be connected straight to the robot control with a single cable. Of these axes, two can be used as the robot’s additional interpolation axis. What makes it different from other systems is that all the additionally connected axes can be programmed just like the robot – and by using the same Teach Box or the RT ToolBox 2. So no extra outlay on software, training or programming.

Boost your productivity

Cycle times of as little as 0.32 seconds with repeat accuracy as low as ±0.02 mm

Flexible work space

504 to 1503 mm reach in a spherical work space – even behind the robot

Teach Box

Full graphic R56TB with touchscreen or R32TB

Configuration

Robot and controller as a complete system or with a PLC module for full PLC functionality of the robot on the iQ platform

Connectors

Pneumatic and electric grippers, Ethernet, USB, camera interface and two encoder connections as well as up to 8 extra axes as standard, operational I/O and field bus extension cards

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com