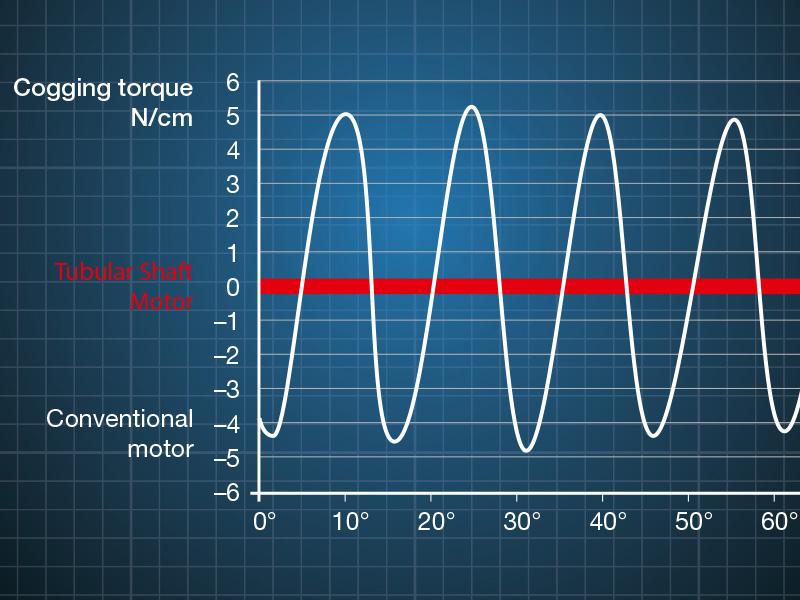

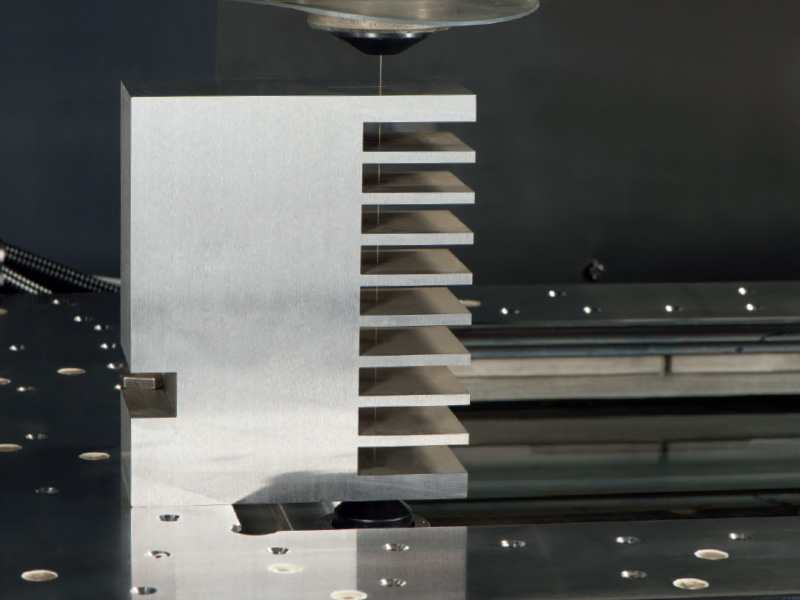

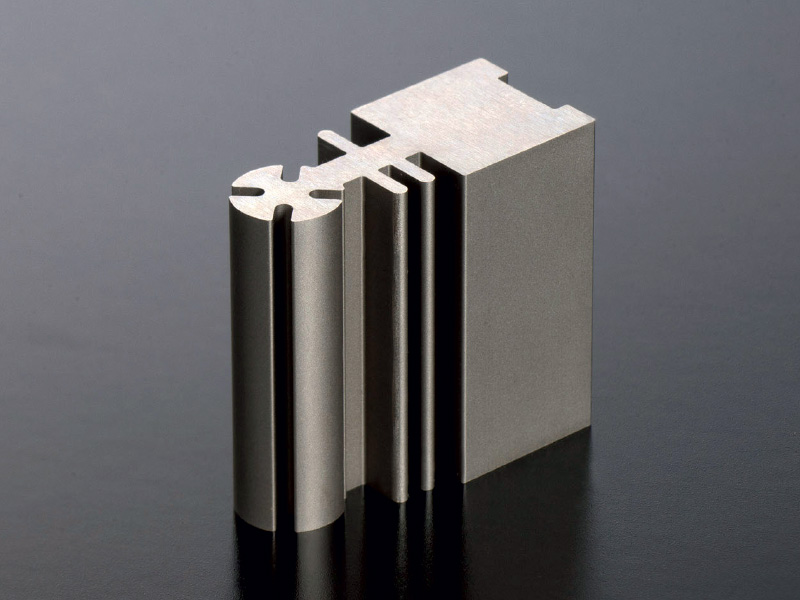

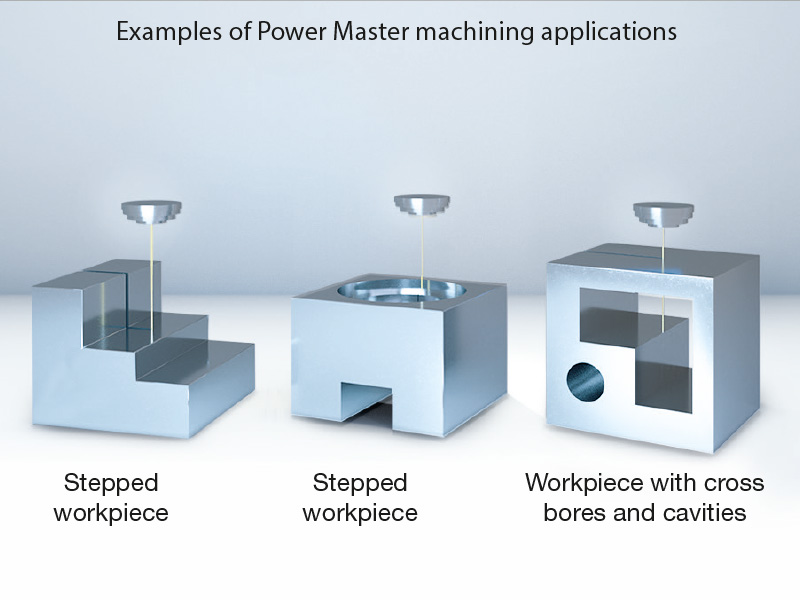

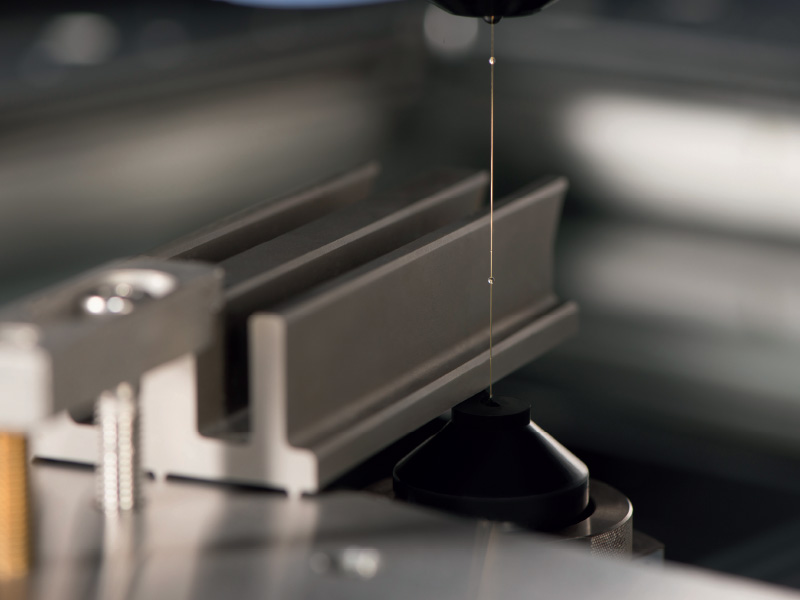

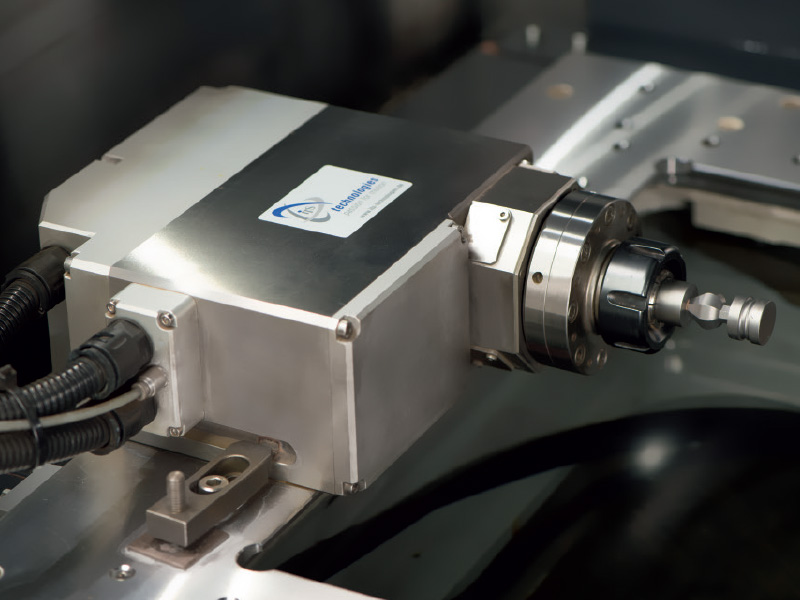

The MV-S series is made for high cutting speeds with a combination of tight tolerances and a low power consumption. With its non-contact Tubular drive and modern technologies it optimizes the wire- and power consumption. Therefore these machines ensure economic benefits which pay off year after year. Finally they are ideal for a reliable man-free operation due to the „Intelligent AT“ wire threading.

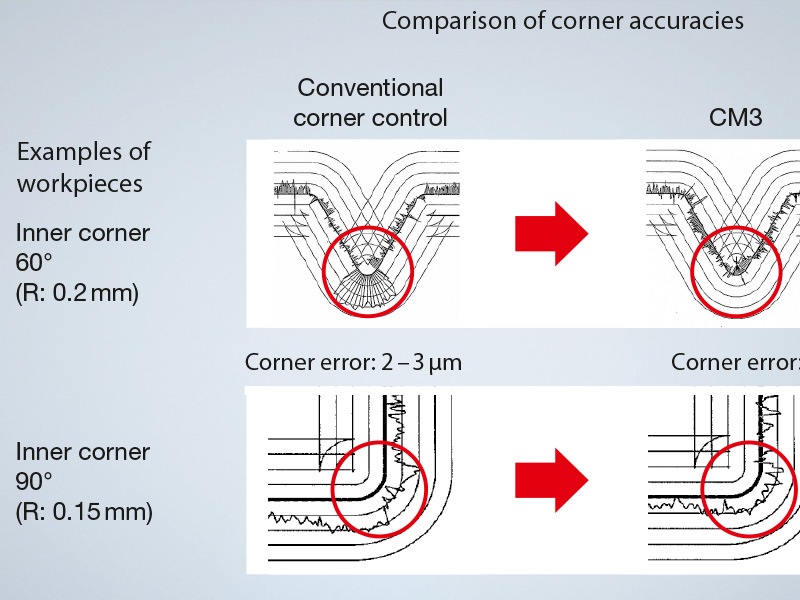

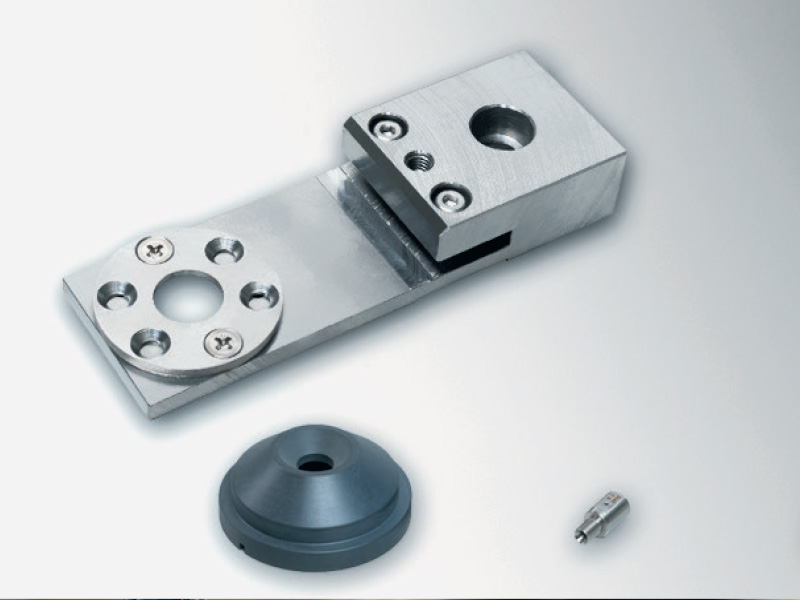

With a general accuracy of ≥ 3 µm and a roughness down to Ra 0.3 µm they can be used for the following production areas:

Welcome to our quick navigation. Here you can directly select a topic that you are particularly interested in. You will then be directed to this topic.

| MV-S Series | X | Y | Z | |

|---|---|---|---|---|

| MV1200S | 400 | 300 | 220 |

| MV2400S | 600 | 400 | 310 | |

| MV2400S Z+ | 600 | 400 | 425 | |

| MV4800S | 800 | 600 | 510 |

| Machine | MV1200S | MV2400S | MV2400S Z+ | MV4800S |

|---|---|---|---|---|

| Travel (X / Y / Z) in mm | 400 / 300 / 220 | 600 / 400 / 310 | 600 / 400 / 425 | 800 / 600 / 510 |

| Travel (U / V) in mm | 120 / 120 (+/- 60) | 150 / 150 (+/-75) | 150 / 150 (+/-75) | 200 / 200 (+/-100) |

| Taper angle (workpiece height) in °/mm | 15 / 200 30 / 87 | 15 / 260 30 / 110 | 15 / 260 30 / 110 | 15 / 355 30 / 155 |

| Max. workpiece dimensions (W x D x H) in mm | 810 x 700 x 215 | 1050 x 820 x 305 | 1050 x 820 x 420 | 1250 x 1020 x 505 |

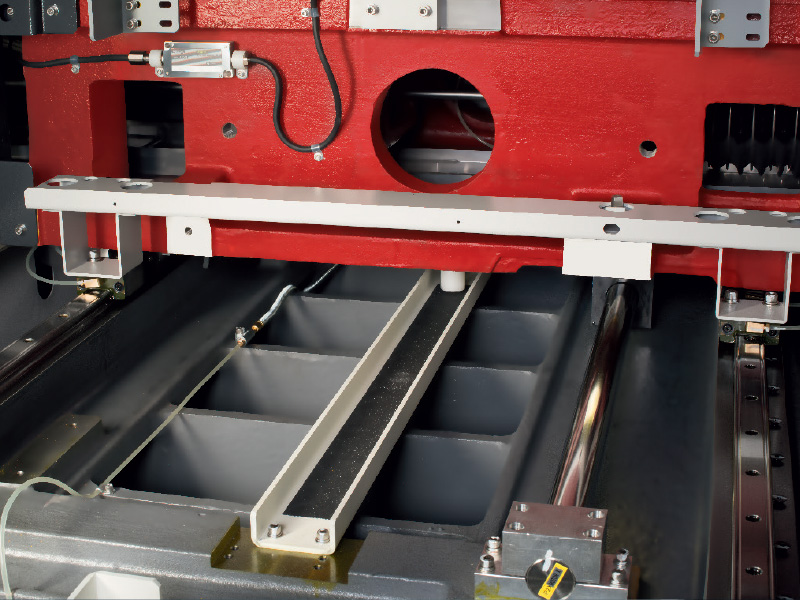

| Max. workpiece weight in kg | 500 | 1500 | 1500 | 3000 |

| Table dimensions (W x D) in mm | 640 x 450 | 840 x 560 | 840 x 640 | 1080 x 780 |

| Table layout | Hardened three-sided table | Hardened four-sided frame table | Hardened four-sided table | |

| Possible wire diameters in mm | 0.1–0.3 | 0.15–0.3 | ||

| Wire spool capacity in kg | 10 | 10 / 16 / 20 / 25 |

||

| Automatic wire threader / wire chopper | Yes / Yes | |||

| Overall dimensions (W x D x H) in mm | 2025 x 2760 x 2015 | 2687 x 3030 x 2150 | 2837 x 3452 x 2380 | 3130 x 3475 x 2815 |

| Machine weight in kg | 2700 | 3500 | 3650 | 5700 |

| Mains voltage | 3-phase 400 V/AC ± 10%, 50/60 Hz, 13 kVA | |||

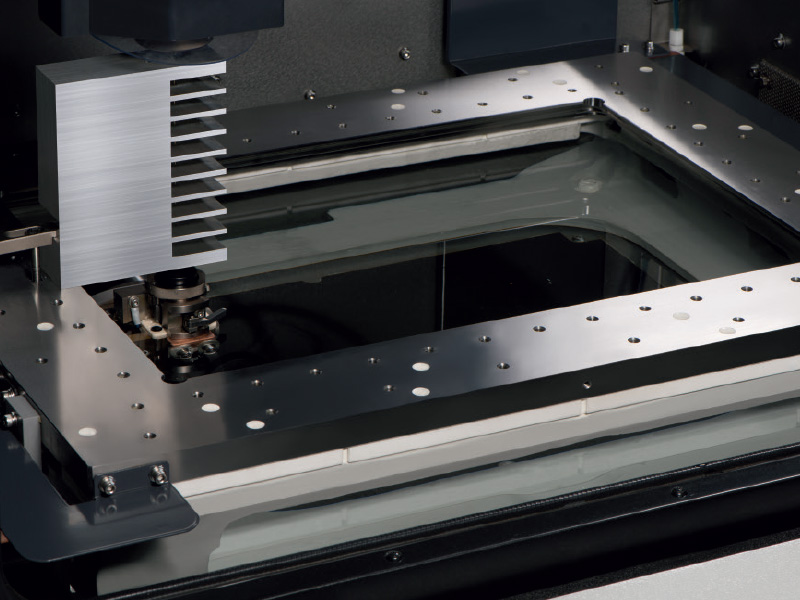

| Filter system | MV1200S | MV2400S | MV2400S Z+ | MV4800S |

|---|---|---|---|---|

| Tank capacity in l | 550 | 860 | 980 | 1480 |

| Filter particle size in µm / filter elements | 3/2 | |||

| Temperature control | Dielectric cooling unit |

|||

| Weight (dry) in kg | Included in machine weight | 350 | 390 | 450 |

| Generator | MV1200S | MV2400S | MV2400S Z+ | MV4800S |

|---|---|---|---|---|

| Power supply unit | Regenerative transistor pulse type | |||

| Cooling method | Fully sealed /indirect air cooling | |||

| Max. output current in A | 50 | |||

| Dimensions (W x D x H) in mm | 600 x 650 x 1765 |

|||

| Weight in kg | 240 | |||

| Control | MV1200S | MV2400S | MV2400S Z+ | MV4800S |

|---|---|---|---|---|

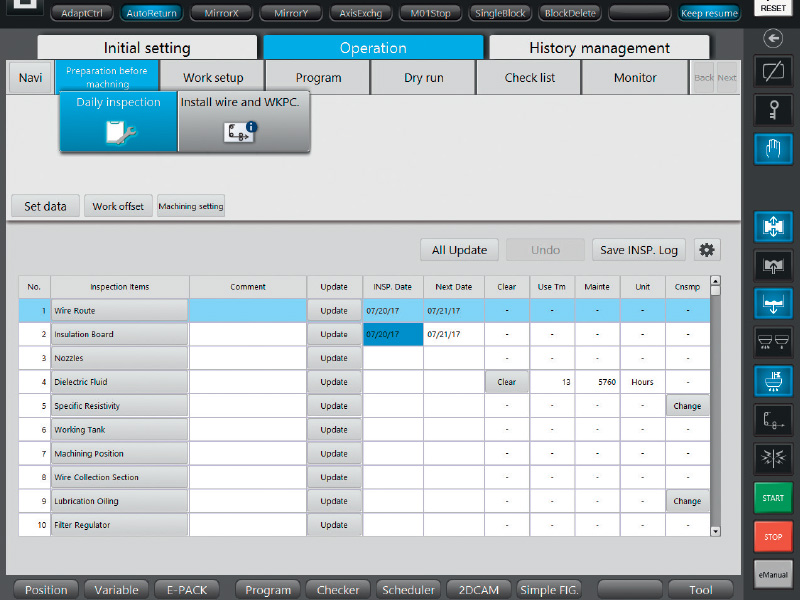

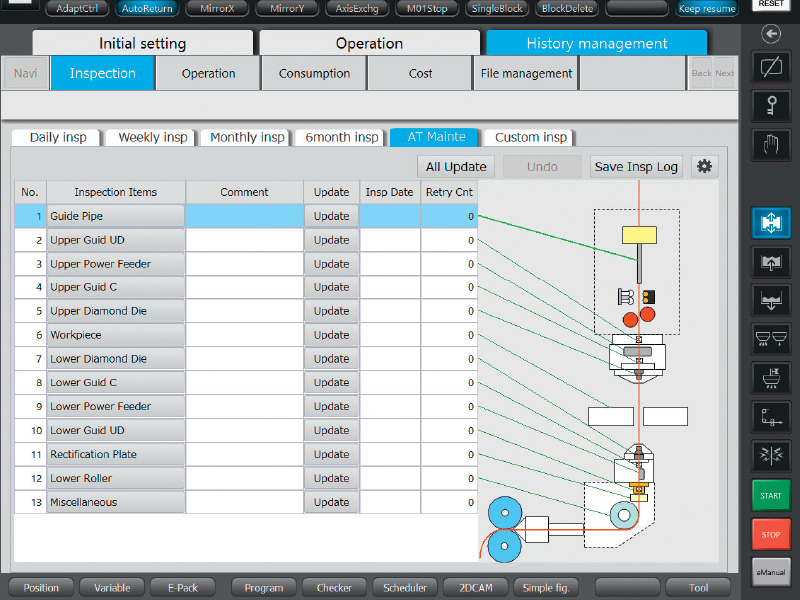

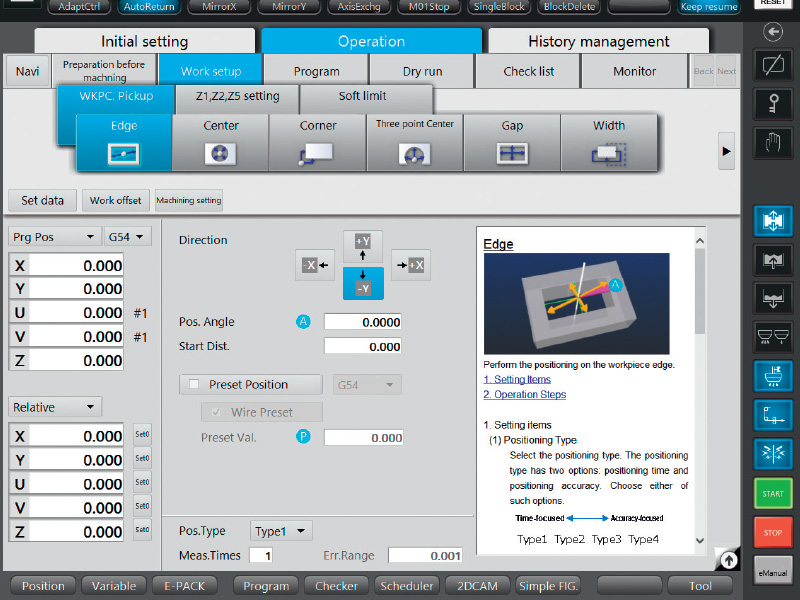

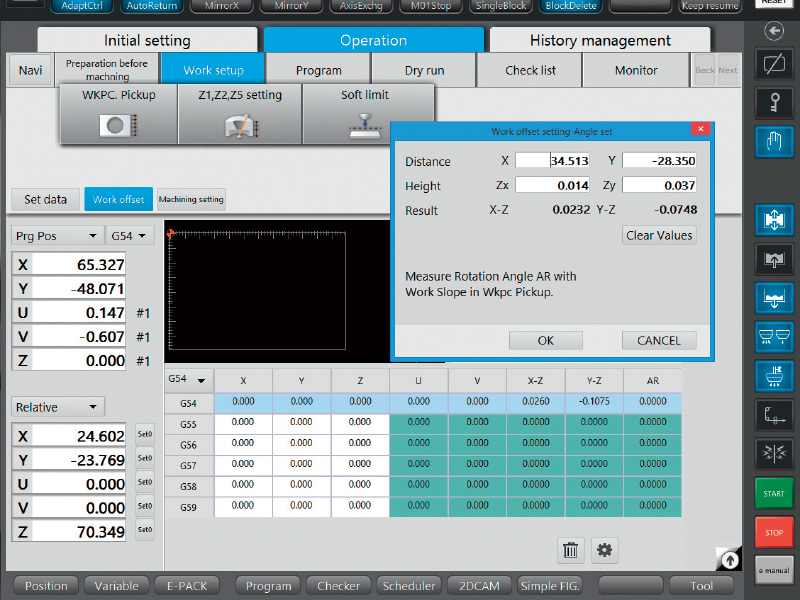

| Input method | Keyboard, USB flash drive, Ethernet, 19” touchscreen | |||

| Control system | CNC, closed circuit |

|||

| Min. command step (X / Y / Z / U / V) in µm | 0.1 |

|||

| Min. axis resolution in µm | 0.05 |

|||

| Equipment | MV1200S | MV2400S | MV2400S Z+ | MV4800S |

|---|---|---|---|---|

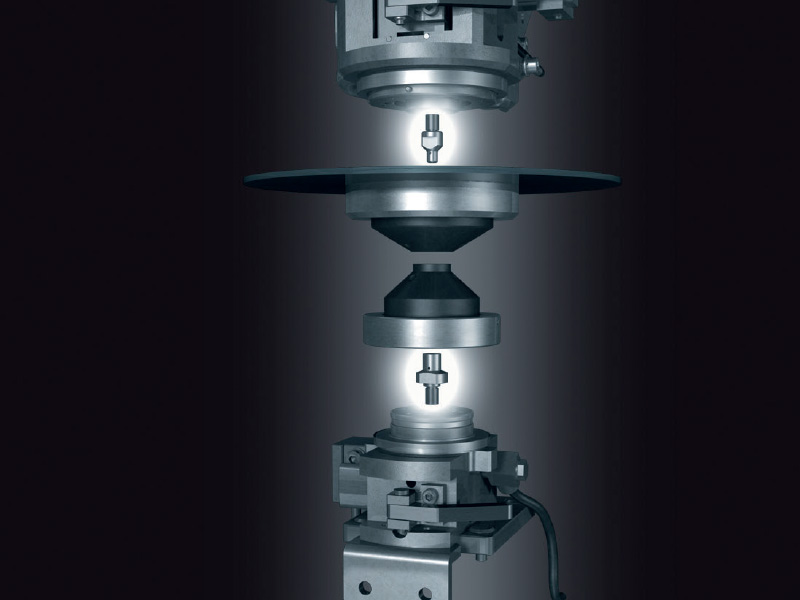

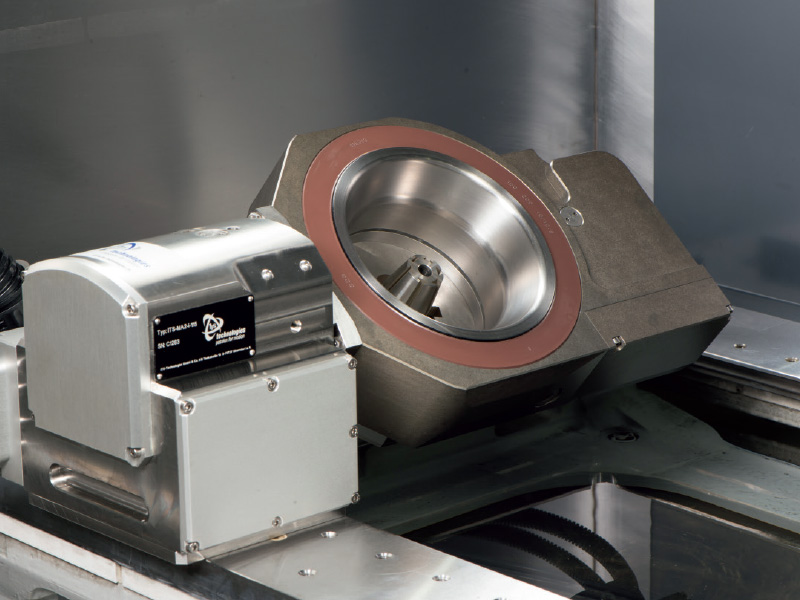

| Tubular Shaft Drives with linear scales (X / Y) | Yes | |||

| Control M800 with 19” full-touch monitor | Yes | |||

| Hand pilot with configurable LCD monitor | Yes | |||

| Vertical front door | Manual | Automatic | ||

| Digital AE II generator | Yes | |||

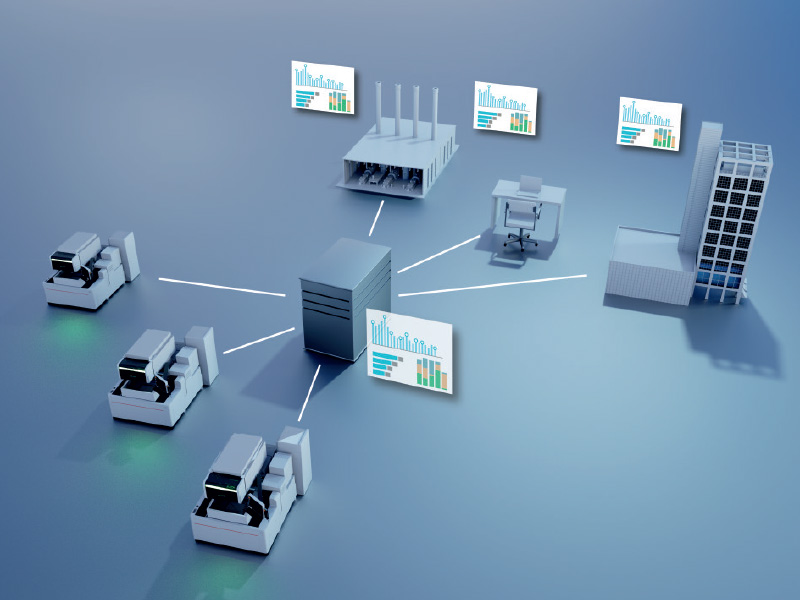

| Ethernet/DNC/FTP | Yes | |||

| Preparation for automation | Optional | |||

| McAfee AntiVirus embedded | Optional | |||

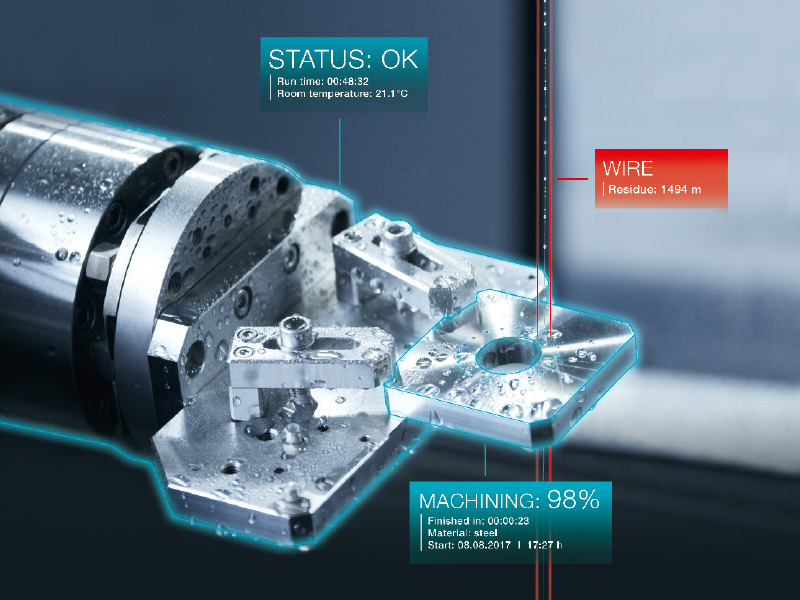

| Production data output | Optional | |||

| 2D CamMagic on-board | Yes | |||

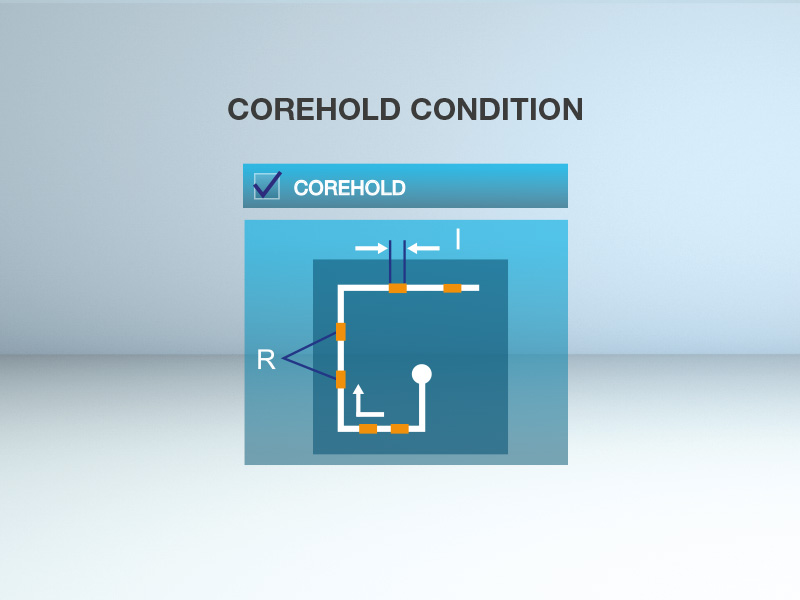

| Corehold technology | Optional | |||

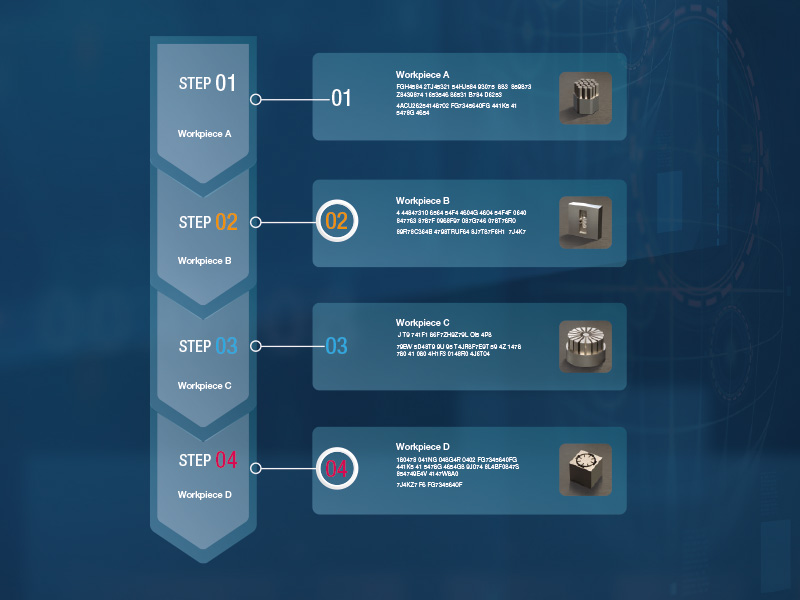

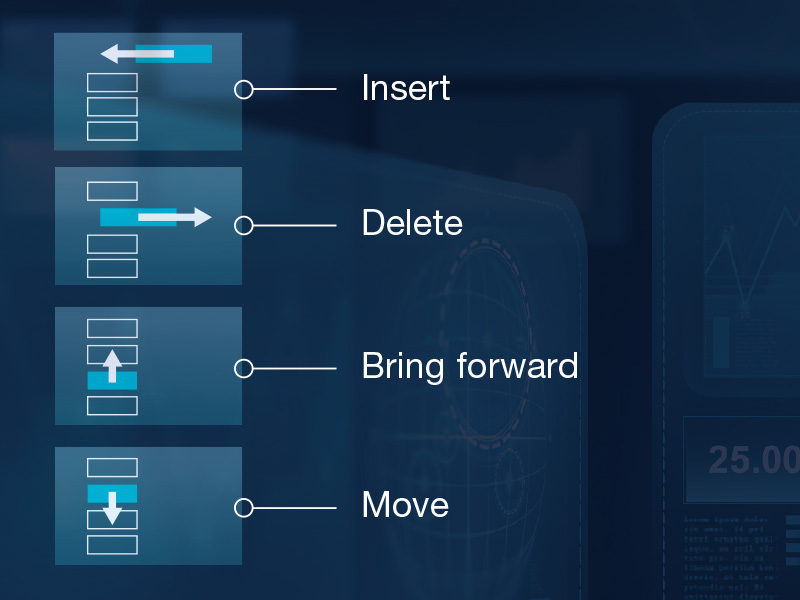

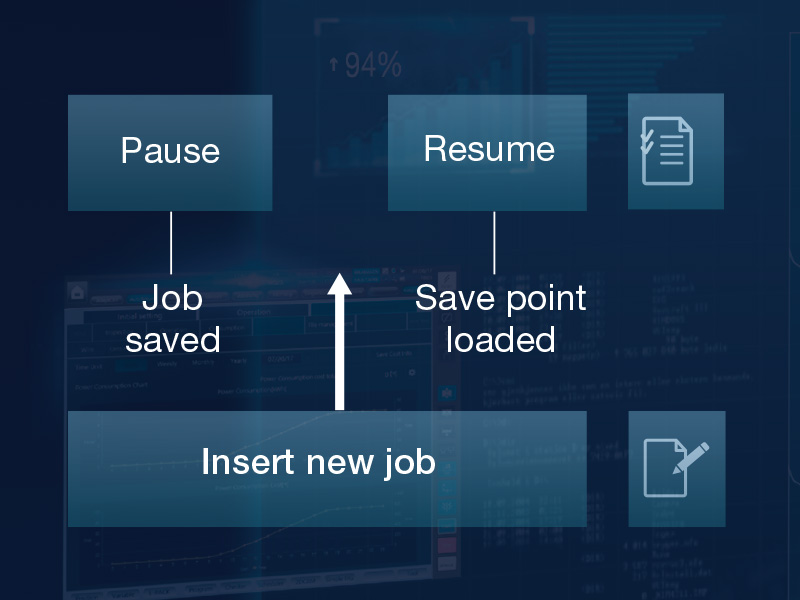

| Job scheduler | Optional | |||

| Sleep mode | Yes | |||

| Optional Hardware | MV1200S | MV2400S | MV2400S Z+ | MV4800S |

|---|---|---|---|---|

| High-Spec package | Optional (not retrofittable) | |||

| Wire station for 16 / 20 / 25 kg wire spools | Optional | Yes | ||

| Wire station for 50 kg wire spools | Optional | |||

| Angle Master Advance II – basic kit including aligning device | Optional | |||

| Angle Master Advance II – wire threading set | Optional | |||

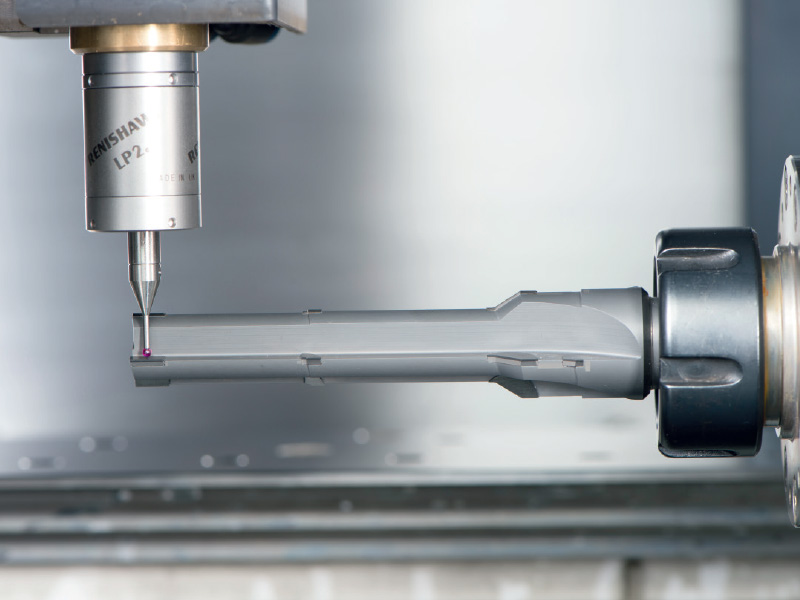

| Automatic Renishaw probe on sleeve | Optional | |||

| ERGO-LUX LED floodlights | Optional | |||

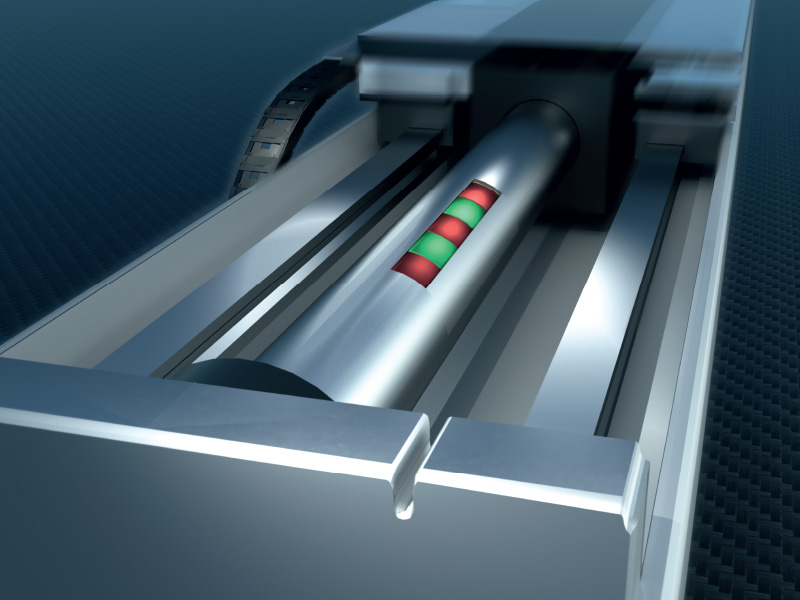

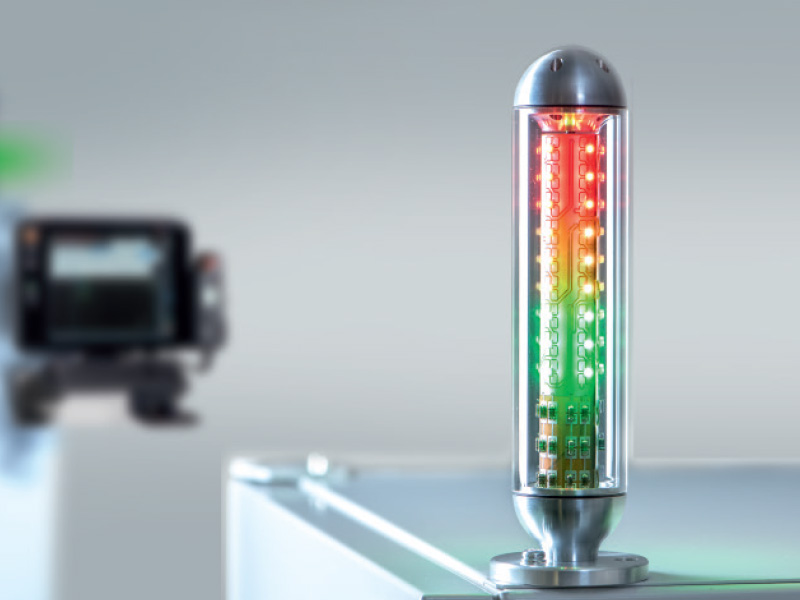

| Tricolour status lamp | Optional | |||

| Automatic dielectric water refilling | Optional | |||

| Connection to external cooling system | Optional | |||

| External signal output with relay circuit board | Optional | |||

| Automatic filter switching system | n/a | Optional | n/a | Optional |

| Optional Tools | MV1200S | MV2400S | MV2400S Z+ | MV4800S |

|---|---|---|---|---|

| Connect Kit | Optional | |||

| 3D CamMagic on-board | Optional | |||

| mcAnywhere Service | Optional | |||

| mcAnywhere Control/ mcAnywhere Control lite | Optional | |||

| mcAnywhere Contact/ mcAnywhere Contact lite | Optional | |||

| Tool package / automation solutions | Optional | |||

Power connection: 3-phase 400 V/AC, PE, ± 10%, 50/60 Hz, primary fuse 32 A slow

Pneumatic connection: 5–7 kgf/cm³, 500–700 kpa, minimum air flow rate 75 l/min, 3/8″ hose connection

The EDM system should be set up on a suitable hard industrial floor and preferably on a consolidated concrete floor. Any shielding that may be necessary in conformity with the EMC Directive is not included in the equipment supplied by Mitsubishi Electric.

The cooling unit contains fluorinated greenhouse gas R410A. For further information, please refer to the associated operating instructions.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com